Optimizing Your Business with Shop Floor Control Systems

Shop floor control systems streamline production, monitor operations, and ensure optimal resource allocation for increased efficiency.

Introduction:

Managing a manufacturing or production facility can be overwhelming without the right systems in place. Shop floor control (SFC) tools are essential for businesses looking to streamline operations, reduce inefficiencies, and maintain clear oversight of their production processes. This article explores how shop floor control systems can help businesses optimize operations and improve overall performance.

What is Shop Floor Control?

Shop floor control (SFC) is a system designed to monitor and manage production processes in a manufacturing environment. It tracks the movement of raw materials, manages the workflow between different stages of production, and ensures resources are used efficiently. SFC systems provide real-time data, enabling businesses to make informed decisions and optimize their production output.

Key Benefits of Shop Floor Control Systems:

- Real-Time Monitoring: Provides up-to-the-minute data on production, allowing businesses to identify and address bottlenecks immediately.

- Improved Resource Allocation: Ensures that machines and labor are used efficiently, reducing downtime and increasing productivity.

- Cost Reduction: By optimizing operations, businesses can reduce waste and minimize production costs.

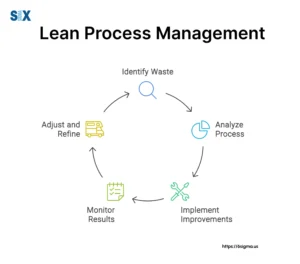

How Shop Floor Control Improves Operational Efficiency

An effective SFC system plays a vital role in enhancing operational efficiency on the shop floor. Here are some ways it contributes to smoother production:

1. Real-Time Data and Reporting

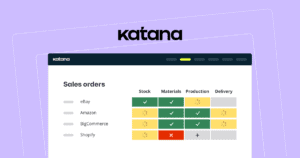

Shop floor control systems offer real-time updates on production metrics such as machine usage, employee performance, and material consumption. Tools like Katana Cloud Inventory and Fishbowl provide live insights into production status, allowing managers to make timely adjustments to keep operations running smoothly.

2. Streamlining Production Workflows

SFC systems automate and simplify complex workflows by assigning tasks to workers, ensuring the right materials are at the correct stations, and monitoring machine performance. This automation reduces the likelihood of errors and ensures that production lines stay on schedule. Cin7 is an example of a tool that integrates workflow automation with inventory and production management, offering seamless shop floor control.

3. Enhanced Inventory Management

SFC systems are often integrated with inventory management tools to ensure that production has access to the necessary materials when needed. This prevents delays caused by material shortages and helps businesses maintain optimal stock levels. Zoho Inventory integrates inventory tracking with shop floor control, keeping the production process flowing smoothly.

4. Labor and Machine Optimization

Shop floor control tools track labor efficiency and machine performance, ensuring that both are operating at their highest capacity. By analyzing this data, businesses can make informed decisions about resource allocation and ensure that no assets are underutilized or overburdened. Systems like Fishbowl help monitor machine downtime and worker output, allowing managers to optimize resource use.

Key Features of Shop Floor Control Systems

Choosing the right shop floor control system depends on your business needs. Look for systems that offer these essential features:

1. Real-Time Data Collection

Real-time data collection ensures that businesses can monitor the progress of every stage of production. Having accurate, up-to-date information allows for swift corrective action if issues arise.

2. Work Order Management

Shop floor control systems should allow businesses to create, manage, and track work orders as they move through production. This ensures that deadlines are met, and that every order follows the correct process.

3. Equipment and Labor Tracking

SFC systems track equipment performance and labor productivity, providing insight into the efficiency of both. Businesses can use this information to make better decisions regarding equipment maintenance and labor scheduling.

4. Integration with Other Systems

A good shop floor control system integrates seamlessly with other business software, including inventory management, ERP systems, and financial tools. This ensures data flows smoothly between departments and provides a comprehensive view of operations.

Common Challenges in Shop Floor Management and How to Overcome Them

Managing a shop floor comes with several challenges, even with SFC tools in place. Here’s how businesses can overcome some of the most common issues:

1. Bottlenecks in Production

Bottlenecks slow down production and cause delays. By using shop floor control systems to monitor workflows, businesses can identify and address bottlenecks as soon as they occur. Real-time data helps pinpoint where processes are stalling, allowing for quick interventions.

2. Equipment Downtime

Machine failures lead to significant downtime and loss of productivity. SFC tools track machine performance, providing data on maintenance needs before breakdowns happen. Preventive maintenance can then be scheduled during low production periods to minimize disruptions.

3. Labor Shortages or Inefficiencies

Without proper oversight, it’s difficult to gauge labor productivity on the shop floor. Shop floor control systems allow businesses to track worker performance and adjust staffing to ensure optimal output. Labor data also helps identify training needs, improving overall efficiency.

FAQs

What is shop floor control?

Shop floor control (SFC) refers to a system used to monitor and manage production activities in a manufacturing environment. It tracks materials, labor, and equipment to optimize workflows and improve efficiency.

How do shop floor control systems benefit businesses?

SFC systems provide real-time data, streamline production workflows, optimize labor and machine usage, and integrate with other systems like inventory management tools, reducing costs and improving productivity.

What features should I look for in a shop floor control system?

Key features include real-time data collection, work order management, equipment and labor tracking, and integration with other systems such as ERP or inventory tools.

Can small businesses benefit from shop floor control systems?

Yes. Even small businesses can benefit from shop floor control systems like Zoho Inventory and Katana Cloud Inventory, which help optimize resources, streamline workflows, and improve overall productivity.

How can shop floor control reduce production costs?

By optimizing resource allocation, reducing waste, and ensuring that labor and machines are used efficiently, SFC systems help businesses cut unnecessary costs and increase profitability.

Top Tools to Simplify and Scale Your Shop Floor Control

- Katana Cloud Inventory – Provides real-time insights into production and inventory, ensuring smooth shop floor operations and optimal resource allocation.

- Cin7 – Offers a comprehensive suite of tools that integrate production management, workflow automation, and inventory tracking, streamlining the shop floor.

- Zoho Inventory – A versatile tool that integrates inventory management with production workflows, ensuring materials are available when needed and reducing delays.

- Fishbowl – Specializes in manufacturing and warehouse management, providing data on equipment performance, labor efficiency, and production status.

- TradeGecko – Now part of QuickBooks Commerce, TradeGecko offers advanced tracking and reporting features to help businesses maintain high levels of operational efficiency.

Keywords: shop floor control, production management, workflow automation, labor tracking, inventory management, real-time data, equipment optimization, manufacturing efficiency