Maximize Efficiency with These Top Manufacturing Tips

Manufacturing success relies on optimizing every step of the process, from sourcing materials to final production.

Manufacturing is at the heart of many industries, but inefficiencies can lead to significant delays, increased costs, and wasted resources. This guide will provide you with actionable tips to streamline your manufacturing process, reduce waste, and increase overall productivity.

1. Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste without sacrificing productivity. By identifying inefficiencies and bottlenecks, companies can save time and resources.

Key Lean Strategies:

- 5S Methodology: Sort, Set in order, Shine, Standardize, and Sustain. These steps ensure a clean, organized workspace that promotes efficiency.

- Value Stream Mapping: This visual tool helps to identify waste and opportunities for process improvement.

- Continuous Improvement (Kaizen): Small, incremental changes lead to significant long-term improvements in efficiency and quality.

2. Invest in Automation and Technology

Automation is transforming manufacturing by reducing human error, speeding up production times, and allowing for more flexible production lines.

Benefits of Automation:

- Reduced Labor Costs: Automation reduces the need for manual labor, allowing employees to focus on higher-value tasks.

- Increased Precision: Automated machines can perform repetitive tasks with greater accuracy than human workers.

- Scalability: Automated processes can be easily scaled to meet increased demand without sacrificing quality or efficiency.

3. Optimize Supply Chain Management

Effective supply chain management is essential for ensuring the timely delivery of raw materials and the smooth operation of manufacturing lines.

Supply Chain Tips:

- Vendor Relationships: Cultivate strong relationships with reliable vendors to ensure consistent, high-quality materials.

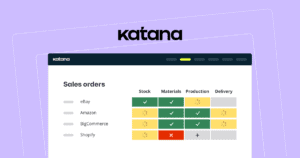

- Inventory Management: Use real-time inventory management tools like Katana Cloud Inventory to avoid stockouts and excess inventory.

- Just-In-Time (JIT) Manufacturing: This strategy reduces inventory costs by receiving materials just as they are needed, reducing storage costs and waste.

4. Focus on Quality Control

Ensuring product quality should be a priority at every stage of manufacturing. Implementing a strong quality control (QC) system prevents defective products from reaching customers, saving time and money on recalls and rework.

Quality Control Strategies:

- Regular Audits: Schedule frequent internal and external audits to ensure adherence to quality standards.

- Statistical Process Control (SPC): Use statistical methods to monitor and control the manufacturing process.

- Employee Training: Ensure that all workers are trained to spot defects early in the process and report them immediately.

5. Use Data to Drive Decisions

In today’s digital world, data is essential for optimizing manufacturing processes. Collecting and analyzing data allows manufacturers to identify inefficiencies, track performance, and make data-driven decisions to improve productivity.

How to Leverage Data:

- Implement IoT Devices: Internet of Things (IoT) devices can collect real-time data on machine performance, downtime, and output.

- Use Predictive Maintenance: Use data analytics to predict when machinery will need maintenance, reducing the risk of breakdowns.

- Performance Metrics: Track key performance indicators (KPIs) such as production speed, defect rate, and overall equipment effectiveness (OEE) to evaluate manufacturing efficiency.

6. Foster a Culture of Safety

A safe manufacturing environment is not only critical for employee well-being, but it also reduces downtime caused by workplace accidents.

Safety Tips:

- Regular Safety Training: Provide ongoing safety training to employees, particularly in high-risk areas such as machine operation.

- Invest in Safety Equipment: Ensure that employees have access to proper safety gear, such as helmets, gloves, and protective eyewear.

- Safety Audits: Conduct routine safety audits to identify potential hazards before they result in accidents.

7. Maximize Equipment Efficiency

Machinery downtime can bring production to a halt, leading to delays and financial loss. Proper equipment maintenance and upgrades can help avoid these issues.

Maintenance Tips:

- Preventive Maintenance: Schedule regular maintenance checks to avoid unexpected equipment failures.

- Upgrade Machinery: Invest in newer, more efficient machines when necessary to keep up with industry standards.

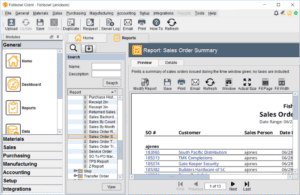

- Monitor Performance: Use tools like Fishbowl to monitor machine performance and track any signs of wear or malfunction.

FAQs

What is Lean Manufacturing?

Lean manufacturing is a method focused on reducing waste while maintaining or improving production quality. It emphasizes efficiency and value in every aspect of the manufacturing process.

Why is automation important in manufacturing?

Automation improves accuracy, reduces labor costs, and allows for greater scalability. It also helps businesses stay competitive by producing higher-quality goods more quickly.

How does batch tracking help in manufacturing?

Batch tracking helps businesses monitor inventory, quality, and production efficiency. It allows manufacturers to trace raw materials and finished goods throughout the supply chain.

How can I improve supply chain management?

Improving supply chain management involves maintaining strong relationships with suppliers, using real-time inventory management, and adopting strategies like Just-In-Time manufacturing to reduce excess inventory.

What tools are available to enhance manufacturing processes?

Tools like Katana Cloud Inventory, Fishbowl, and Zoho Inventory offer automation, real-time monitoring, and data analytics that streamline operations and boost efficiency.

Top Tools to Simplify and Scale Your Manufacturing Process

- Katana Cloud Inventory – This tool offers real-time tracking of inventory, raw materials, and finished goods. It also integrates with multiple platforms to automate production planning.

- Fishbowl – Fishbowl helps streamline inventory management, production tracking, and purchasing, offering robust solutions for manufacturers of all sizes.

- Zoho Inventory – Zoho Inventory provides businesses with comprehensive tools for managing stock, automating purchase orders, and integrating with various sales channels.

- Vendasta – Vendasta’s automation tools help manufacturers simplify sales pipelines and manage customer relationships more efficiently.

- Drip – Drip offers automated marketing and CRM solutions to help manufacturers stay in touch with customers and drive long-term sales growth.

Keywords: manufacturing tips, lean manufacturing, supply chain management, automation, inventory management, quality control, preventive maintenance, production efficiency, manufacturing tools