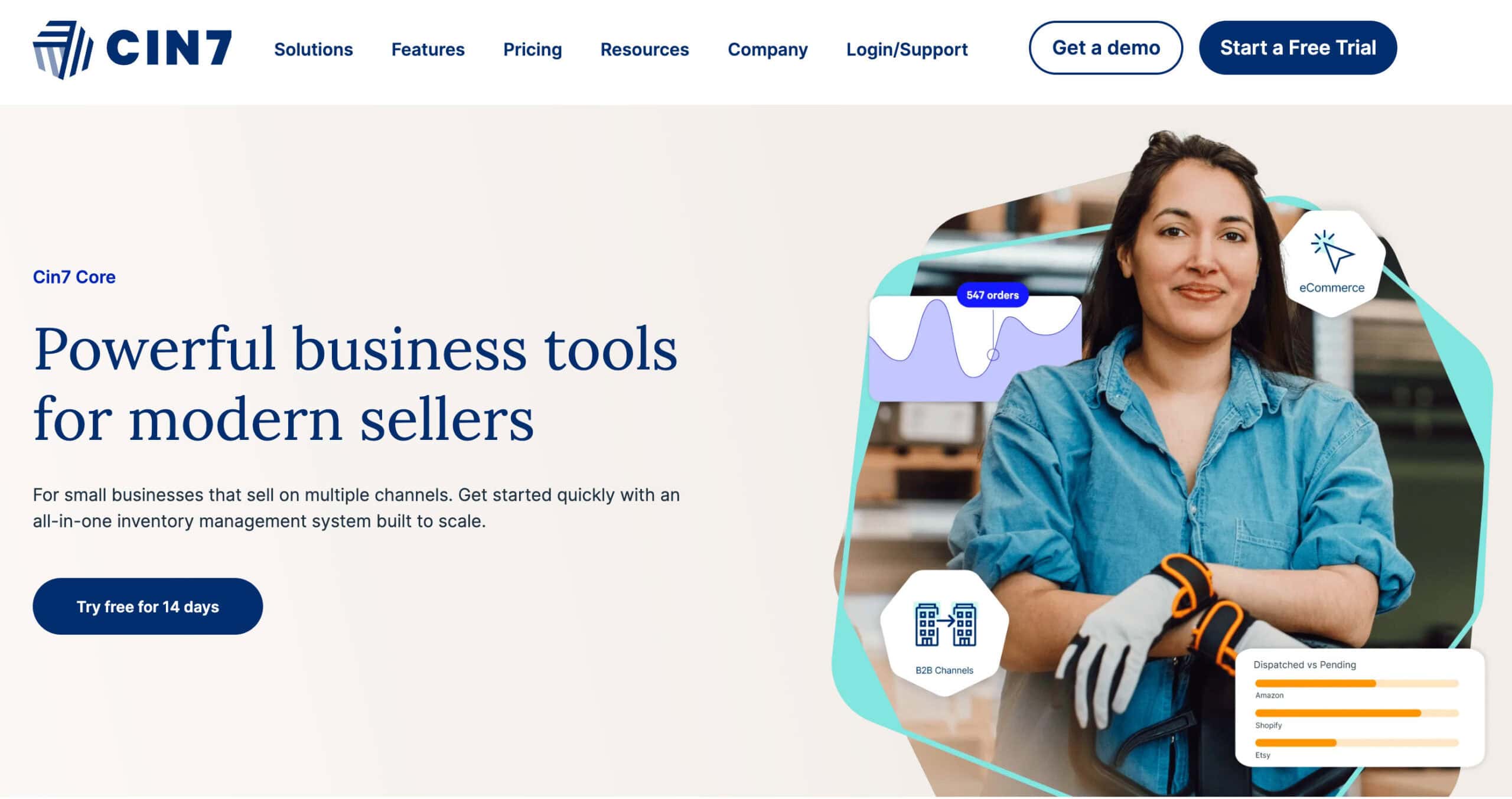

Top Cin7 Features for Manufacturing Efficiency

Unlock manufacturing efficiency with Cin7’s top features designed for optimal production management.

Introduction

In today’s competitive manufacturing landscape, efficiency isn’t just an advantage—it’s a necessity. Managing production processes, inventory levels, and supply chains can be overwhelming without the right tools. Cin7 offers a comprehensive solution with features specifically designed to enhance manufacturing efficiency. This article delves into the top Cin7 features that can transform your manufacturing operations.

Understanding Cin7’s Role in Manufacturing

Why Efficiency Matters

- Cost Reduction: Streamlined processes lower operational costs.

- Improved Productivity: Efficient workflows increase output.

- Competitive Advantage: Enhanced efficiency positions you ahead of competitors.

How Cin7 Fits In

Cin7 is a cloud-based inventory management system that integrates production, inventory, sales channels, and supply chain into one platform. This integration simplifies complex processes, reduces errors, and boosts productivity.

Top Cin7 Features Enhancing Manufacturing Efficiency

1. Advanced Production Management

Bill of Materials (BOM)

- Detailed BOM Creation: Define components and materials for each product.

- Version Control: Manage different versions of BOMs for product variations.

Work Orders

- Automated Generation: Create work orders based on sales orders or inventory levels.

- Progress Tracking: Monitor the status of work orders in real-time.

Benefits:

- Accuracy: Minimize errors in production planning.

- Efficiency: Streamline the production process from start to finish.

2. Real-Time Inventory Tracking

Multi-Location Management

- Global Visibility: Track inventory across multiple warehouses and locations.

- Centralized Data: Access real-time stock levels from a unified dashboard.

Stock Alerts

- Low Stock Notifications: Receive alerts when inventory reaches reorder points.

- Overstock Prevention: Avoid excess stock that ties up capital.

Benefits:

- Optimized Inventory Levels: Balance supply and demand effectively.

- Reduced Costs: Minimize holding costs and prevent stockouts.

3. Demand Forecasting and Inventory Planning

Data-Driven Forecasting

- Historical Analysis: Use past sales data to predict future demand.

- Seasonal Trends: Account for fluctuations in demand during different periods.

Automated Reordering

- Reorder Points: Set minimum stock levels to trigger automatic purchase orders.

- Supplier Integration: Streamline communication with suppliers for timely restocking.

Benefits:

- Proactive Management: Anticipate needs before they become issues.

- Supply Chain Efficiency: Maintain smooth operations with timely inventory replenishment.

4. Shop Floor Control

Resource Allocation

- Labor Management: Assign tasks to employees based on availability and skill set.

- Equipment Utilization: Schedule machinery to maximize uptime.

Production Scheduling

- Gantt Charts: Visualize production timelines and dependencies.

- Real-Time Adjustments: Adapt schedules on the fly to address changes.

Benefits:

- Enhanced Productivity: Optimize use of resources for better output.

- Reduced Downtime: Minimize delays and bottlenecks in production.

5. Integration with Sales Channels

Omni-Channel Support

- E-commerce Platforms: Seamlessly integrate with Shopify, WooCommerce, and more.

- B2B Sales: Manage wholesale orders alongside retail sales.

Unified Order Management

- Centralized Processing: Handle all orders from different channels in one place.

- Consistent Inventory Data: Ensure accurate stock levels across all platforms.

Benefits:

- Improved Customer Satisfaction: Deliver products promptly by avoiding stock discrepancies.

- Simplified Operations: Reduce complexity in managing multiple sales channels.

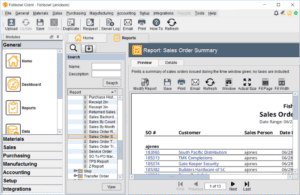

6. Comprehensive Reporting and Analytics

Customizable Reports

- Inventory Reports: Analyze stock movements and turnover rates.

- Sales Analysis: Identify top-performing products and sales trends.

KPI Monitoring

- Dashboards: Monitor key performance indicators in real-time.

- Exportable Data: Share insights with stakeholders easily.

Benefits:

- Informed Decision-Making: Base strategies on accurate data.

- Continuous Improvement: Identify areas for operational enhancements.

Implementing Cin7 for Maximum Efficiency

Steps to Get Started

- Assessment: Evaluate your current processes and identify pain points.

- Customization: Configure Cin7 features to align with your operational needs.

- Training: Educate your team on using the system effectively.

- Integration: Connect existing systems and platforms for seamless data flow.

Support and Resources

- Onboarding Assistance: Benefit from Cin7’s implementation support.

- Ongoing Training: Access tutorials, webinars, and knowledge bases.

- Customer Service: Reach out to Cin7’s support team for any issues.

Success Stories

Case Study: ABC Manufacturing Co.

Challenge: ABC Manufacturing struggled with inventory inaccuracies and production delays.

Solution: Implemented Cin7’s advanced production management and real-time tracking.

Results:

- Inventory Accuracy Improved by 40%

- Production Efficiency Increased by 35%

- Reduced Stockouts and Overstocks

Testimonials

- Operations Manager: “Cin7 transformed our manufacturing process, making us more efficient than ever.”

- Inventory Specialist: “Real-time tracking has been a game-changer for our inventory management.”

Conclusion

Cin7’s robust features offer manufacturers the tools needed to enhance efficiency significantly. From advanced production management to comprehensive analytics, Cin7 empowers businesses to streamline operations, reduce costs, and stay competitive. By integrating these features into your manufacturing processes, you can achieve greater productivity and set the stage for sustained success.

FAQs

Is Cin7 suitable for small to medium-sized manufacturers?

Yes, Cin7 is scalable and customizable, making it ideal for businesses of all sizes looking to improve manufacturing efficiency.

How does Cin7 assist with demand forecasting?

Cin7 analyzes historical sales data and market trends to provide accurate demand forecasts, helping you plan inventory and production accordingly.

Can Cin7 integrate with my existing systems?

Cin7 offers integrations with various platforms, including accounting software like QuickBooks, e-commerce platforms, and more, ensuring seamless data flow.

What kind of support does Cin7 offer during implementation?

Cin7 provides onboarding assistance, training resources, and ongoing customer support to ensure a smooth implementation process.

How does real-time inventory tracking benefit manufacturers?

Real-time tracking allows you to monitor stock levels instantly, reducing the risk of stockouts or overstocking and enabling more efficient inventory management.

Top Inventory Management Tools for Manufacturers

Enhance your manufacturing operations with these leading tools:

Cin7

A comprehensive platform offering advanced production management, real-time inventory tracking, and robust analytics tailored for manufacturers.

Katana Cloud Inventory

Specializes in production planning and shop floor control, providing real-time insights into manufacturing processes.

DEAR Systems

Combines inventory management with accounting and sales features, ideal for manufacturers seeking an integrated solution.

Fishbowl

Offers manufacturing and warehouse management solutions with advanced tracking and automation capabilities.

Zoho Inventory

Provides multi-channel inventory management with strong reporting features, suitable for businesses of various sizes.

Keywords: Cin7 features, manufacturing efficiency, production management, inventory planning, shop floor control, inventory tools, manufacturing tips, cloud-based inventory, operational efficiency, demand forecasting